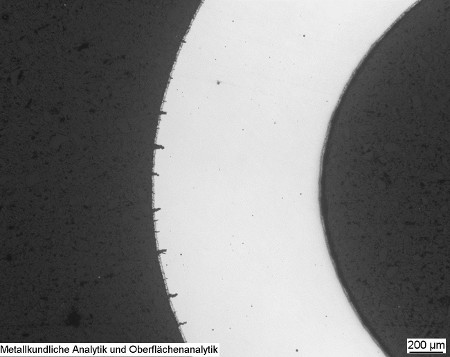

Figure 1: Deep cracks are found in hot formed zinc coated samples. Graphic: Voest Alpine.

Position Indication:

Content

2011 - Klaus-Dieter Bauer

Modeling Liquid Metal Embrittlement

Diplomarbeitsprojekt: Forschungsaufenthalt am Max-Planck-Institut für Eisenforschung Düsseldorf, Deutschland

03.04.2011 – 29.07.2011

Klaus-Dieter Bauer

Contact: bauer dot klaus dot dieter (at) gmail.com

1 Motivation

Quality steel products currently exploit the favourable properties of martensite, a phase of iron obtained by austenizing and quenching ferrite.

When producing hardened work pieces from plates of zinc coated steel currently an indirect process is applied: The steel is formed in its cold ferrite state, austenized by annealing at high temperature and then press hardened (that is, quenched in a press). Theoretically money and time can be saved by applying the direct process, where the deformation takes place after heating the steel, as the technical requirements for the austenitization furnace are simplified and hot forming can be done in the same press as the press hardening – in a single step.

Experiments however show, that deep cracks (up to to order of 100μm) result. Experiments at VOEST-alpine showed, that this is caused by a Liquid Metal Embrittlement effect of the iron bulk by liquid zinc found at the annealing temperatures. This and further experimental information I received in discussions with Dipl. Ing. Siegried Kolnberger and Dipl. Ing. Harald Schwinghammer from VOEST-alpine.

Purpose of the thesis under supervision of Prof. Dr. DI Kurt Hingerl is to contribute to clarifying the effects involved by doing theoretical calculations on the material system applying Density Functional Theory in cooperation with the Computational Materials Design department at the Max-Planck-Institut fuer Eisenforschung in Duesseldorf, the latter providing us with knowledge on numerical treatment of steel and supervision for the numeric part of my work in general.

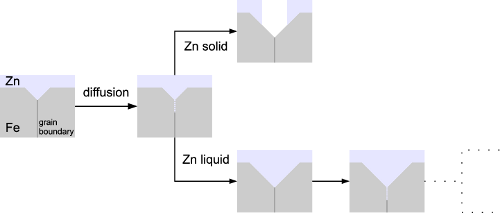

Figure 2: Rather than modeling the influence of zinc’s liquidity explicitly, we just assume, that the liquid phase is to blame for zinc being available at crack tips.

2 Method and Theory

In the very first discussions with Prof. Dr. Jörg Neugebauer (head of CM department of MPIE) and Dr. Mira Todorova (my on-site supervisor) at Duesseldorf we concluded not to model the dynamics of the embrittlement. Based on their experience it was clear, that within the scope of a diploma thesis we would have to limit our considerations to energetic arguments (a Griffith model), i.e. “does zinc prefer to be at an iron grain boundary rather than in a zinc reservoir?” and “does zinc wetting reduce the energy difference between a grain boundary and a crack?”, whereas we won't investigate, whether barriers prevent the transistions involved. Neither will we model zinc's liquid state explicitly: We just assume that liquidity provides the ability of the “zinc reservoir” to stay close to the propagating crack tip.

We concluded from these requirements, that I need to calculate energies for atoms in bulk reservoirs as well as surface and grain boundary interface energies in order to answer aforementioned questions. As DFT is a ground state theory (i.e. the values directly obtained are for a temperature near 0K ), it's planned to extend these result with thermodynamic models to the relevant high temperatures later.

Based on experimental input it was decided to use ferrite (bcc iron) in our calculations: While the economic relevance of the effect is mostly about embrittlement of the austenite phase after annealing but before quenching, comparison experiments found it in ferrite as well – and ferromagnetic ferrite is like to cause less computational problems than antiferromagnetic austenite.

Furthermore the use of VASP was suggested as for iron PAW potentials should be used. Those are better tested for VASP than e.g. for ABINIT.

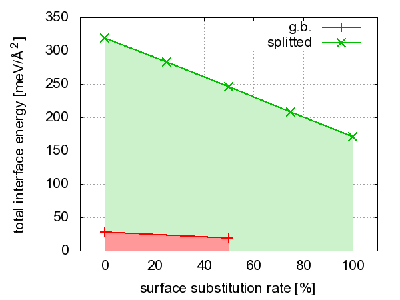

Figure 3: Energetic comparison of the partially substituted Σ3 g.b. and the corresponding surface reconstructions. As there are two surfaces, a 50% average surface substitution rate corresponds to a 100% substituted grain boundary layer. Data for a second g.b. substitution layer has not yet been generated, apparently the dominant contribution to embrittlement comes from the surface energies anyway.

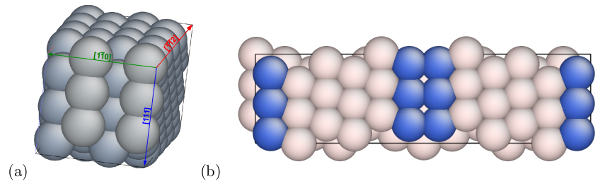

Figure 4: (a) The Σ3 grain boundary corresponds to a [112] surface. (b) View of a sample supercell along the [110] direction. Colour encodes different coordination numbers. The atomic positions are relaxed, yet there is barely free volume at the grain boundary.

3 Workflow

First reference values for bcc Fe and hcp Zn bulk systems where needed. These were calculated for 2-atomic unit cells. By varying the unit cell volume we also obtained the bulk moduli in sufficient agreement with experiment (i.e. the agreement is not exactly good for Zn in particular but within the 10 GPa range usually found in DFT.) by fitting the Energy( Volume ) curve to the Birch-Murnaghan equation of state and the cohesion energy by comparing to atom in a box (i.e. converging against a free atom by putting an atom into a large unit cell and observing convergence of the energy with growing volume.) calculations. These values were mostly used to check the computational results for plausibility. Zn calculations surprisingly proved difficult to converge. It took some time to find out, that obtaining acceptable convergence of the c/a parameter of the hcp lattice requires a dense 64×64×64 k-point grid.

Next we discussed which grain boundaries (and equivalent surfaces) to do calculations for. We decided to try at least a Σ3 and Σ5 grain boundary and found a Σ5 38 tilt grain boundary being close to a grain boundary mentioned in literature and only an almost bulk like 60 tilt g.b. for Σ3.

For the Σ3 g.b. I analyzed grain boundary energies as well as surface energies for pure iron as well as for partial and full substitution of the surface or respectively the g.b. layer with zinc. Originally we had planned to test insertion sites near the g.b. as well, but the relaxation of the Σ3 g.b. revealed barely free volume, i.e. there is no space, where one could squeeze in zinc atoms (which are bigger than iron ones). For the Σ5 g.b. however insertion sites are expected to be relevant. Equally a series of tests showed that just replacing the surface layer in surface (i.e. slab) calculations give the optimized geometry after relaxation.

When calculating the surface energies for different coverage rates and substitution geometries, we found that there is no dependence on substitution geometry, which greatly simplifies the considerations (e.g. when splitting at the grain boundary, it shouldn't matter how the Zn atoms are distributed onto the two surfaces). From Fig. 3 one can see, that indeed the presence of even a single Zinc layer reduces the energy needed for splitting a surface significantly (and that zinc favors to be at an iron grain boundary over being in a bulk zinc reservoir). Of course this analysis could be done in more detail (verifying a linear behaviour of the `g.b.' curve as well, second substitution layer at the grain boundary...), but at least for the Σ3 g.b. I will not do this in favor of the more realistic Σ5 g.b.

Obtaining the data for the zinc wetted grain boundary proved non-trivial. Due to zinc requiring more space than iron, the supercells containing zinc were under compressive stress effectively, which had to be relaxed in order to obtain acceptable convergence with respect to super cell size. In pure iron calcuations, the bulk lattice parameters could be used without relaxation.

Close to the end of my stay I started analyzing the density of state (DOS) of supercells. Better interpretation of this data is yet to be obtained.

4 Links

http://www.mpie.de/ Max-Planck-Institut für Eisenforschung, Düsseldorf

http://www.jku.at/zona Zentrum für Oberflächen und Nanoanalytik, JKU Linz

Audit hochschule und familie

Audit hochschule und familie