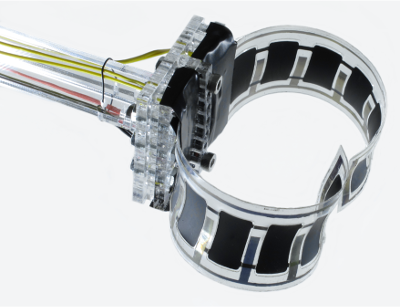

Figure 1: a) Soft Robotic Gripping Device (DEMES) Mounted in Gripper Configuration.

Position Indication:

Content

2015 - Jürgen Kratochwill

Dielectric Minimal Energy Structures

Research stay at the EPFL-LMTS (Microsystems for space technologies

laboratory of the Ecole Polytechnique Fédérale de Lausanne)

Sep, 28, 2015 - Nov, 29, 2015

Jürgen Kratochwill

Contact: vorname.nachname(/\t)jku.at

When I first heard about the opportunity to work abroad for two month on my master thesis I was immediately caught by the idea and committed to make it happen. I saw the opportunity to gather interesting experiences abroad and take the next step in my already solid education. Thanks to the connections of my supervisor Ingrid Graz, various institutions of the JKU and the Macke foundation the Microsystems for Space Technologies Laboratory (EPFL-LMTS) in Neuchâtel, Switzerland was the target for my exchange. Amongst an international motivated team it was easy to keep the spirits high and archive qualitative characterization of my sensors response to the actuation of a physical soft robotic gripping device (see Figure 1) originally developed at LMTS. Long term stability testing and producing high quality pictures (see Figure 1) for a potential succeeding publication were the final desired outcome hence contributing to my thesis and professional experience.

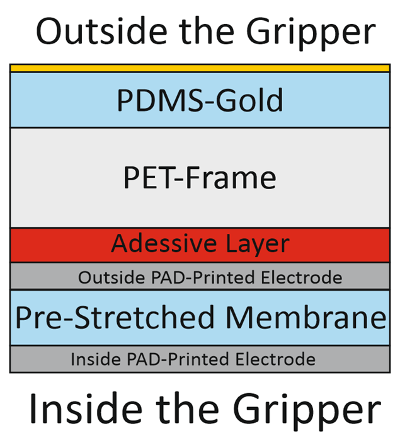

Figure 1: b) Shows the multilayered buildup of a DEMES device

Work Description

The months of intense work at LMTS involved various tasks expanding the original scope of my project, steep learning curves to operate the necessary machines and master the involved manufacturing techniques of dielectric minimal energy structures (DEMES) developed in their laboratory. Those processes enabled me to tailor the prototype devices to my needs and combine them with the sensing technique I developed.

Mechanical Fabrication

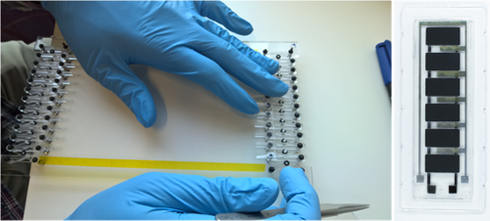

I took part in a cleanroom training where I learned about correct behavior when working in such a place as many of the required steps to manufacture a multilayered device as portrayed in Figure 1b require a dust free environment. I learned to produce micrometer thick elastomeric membranes, pre-stretch them to the necessary elongation for a working DEMES and autonomously operate an industrial PAD-printing machine for applying the elastomeric electrodes onto the membrane acting as the inner part of the device as seen in Figure 1b.

Figure 2 a) (left) manual prestretching of an elastomeric membrane with a custom built laser machined frame b) (right) prestretched membrane with double sided electrodes and applied frame

Measurement

When a voltage is applied on the electrodes of the DEMES, the elastomer between deforms due to electromechanical forces resulting, due to its unique shape, in opening of the gripper. The change of bending angle of the whole device alters the surface strain influencing the shape of the thin gold film on the outside (see schematic Figure 1b). The change in resistance of the nanometer film can be measured and correlated with the movement of the device.

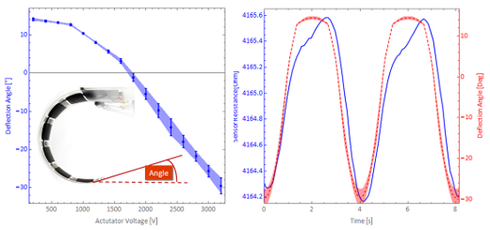

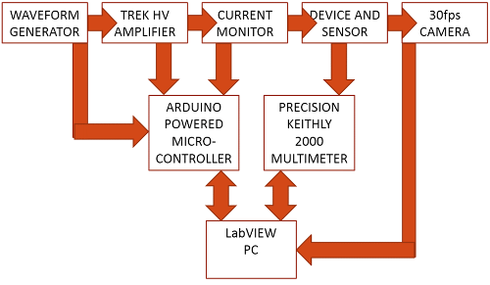

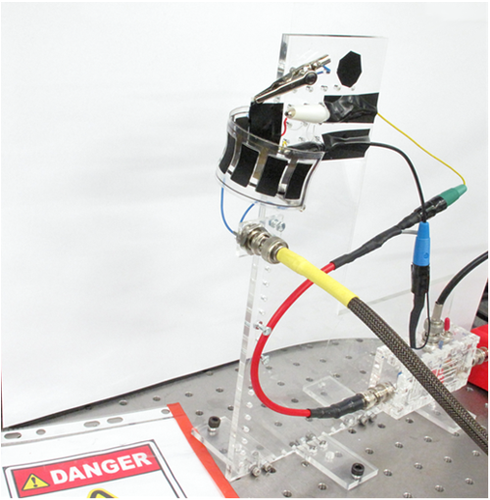

In order to characterize the DEMES-Sensor combination I built a laser-machined sample stand and arranged a setup according to Figure 3. I used a waveform generator paired with a high voltage amplifier to drive the DEMES actuation, a precision Keithly multimeter to measure the resistance change of the gold film and a microcontroller to control the setup. I wrote an interface between microcontroller and LabView, logging all measured data to a PC. Further I visually correlated the tip angle of the device to the applied voltage in order to combine the measured resistance with to the mechanical state of the device. The results of the angular measurements are shown in Figure 4a. Figure 4b shows the resistance signal follows the mechanical tip angle of the device. The signal shape is under further investigation but seemed to be stable even after 150000 actuation cycles.

Figure 3 a) Schematic illustration of my characterisation setup

Figure 3 b) Shows a sample mounted into the custom made laser machined Plexiglas stand

Figure 4 a) (left) shows the correlation between the tip angle of the DEMES device and the applied voltage b) (right) shows the sensor response of the device actuated by a 0.25 Hz sinusoidal signal

Personal Impressions

What did I have in mind about in Switzerland before my stay? Alps, conservative people, right winged, chocolate, cheese, trains and presumed higher quality of living than Austria. As countries with a potential higher living standard than good old Austria are hard to come by therefore that point alone seemed worth some investigation.

There I was, still jet lagged from pulsating life in Tokyo, arriving in two goat, 1000 wine plant beautiful backwater village Le Landeron. Eager to discover my new environment on inline skates I was hammered by the rocky roads and the equally hard realization that there is not much more to the town than the stunning scenery. I could not revise the first impression of lifelessness even I highly enjoyed lying by the lake in the most likely due to global climate change ridiculously warm autumn sun. The same conditions enabled traditional sausage lab outings, Swiss cheese (which is delicious but not better than Austrian one) fondue, organizing sunset sushi events and Potlucks with my international colleagues (3 times more internationals than locals!!) where some of them quickly turned into dear friends regardless of the short term we could spend together. It became clear to me that a diverse international work environment is a necessity for me to thrive therefore I had no troubles in keeping up my positive energetic vibe during my stay and foster a desirable outcome.

The very same attribute helped me to easily dive into the club driven culture which are essential parts of Swiss life. Pumpkin carving with the English Conversation club in Bern, multiple Toastmaster club meetings, playing at badminton club and starting conversations with people while travelling the cities helped me to get a deeper insight into the Swiss culture which seemed remarkable similar to Austrian. Astonishing till the very end that a country made up by individual regions with different languages, laws, public transport providers and taxation systems can form and act as a country while people still seem to be content about the amount of involved bureaucracy as long as there is enough snow to ski on.

In Austria we are already doing a pretty good job in keeping the difference between rich and poor in check still it took me a while to wrap my around that a supermarket employee in Switzerland earns more than middle management with a master’s degree at home resulting in even higher freedom in spending one’s personal resources. While supermarket prices are perceived about 30% higher than in Austria, service or location activities can easily climb 500% difference. 24 Euro for a single Cinema ticket with 40min advertisement break?? 30 Euro for a simple meal? No wonder that many colleagues refrained from eating the 12 Euro rather mediocre quality cantina meal and consistently prepared their own food from the supermarket. On the one hand I am certain by now it is easy to travel and pile up money on a Swiss wage paired with smart choices. On the other hand I had the impression that the vast open opportunities trap many people in an empty short time happiness focused mindset without long term goals to thrive for.

After two months, packed with delicious chocolates and riding a non-cancelled Austrian train back home, passing standardized Swiss houses and beautiful snowy Alps, I carry more than just my luggage. I have a bag full of new experiences just beside me. Switzerland seems like a compelling country to live in but really better than Austria? – I am not convinced about that.

Audit hochschule und familie

Audit hochschule und familie